In recent years, the use of n2 nitrogen generators has gained significant attention in various industries. These generators are designed to produce high-purity nitrogen gas by separating it from the surrounding air. This article aims to analyze the industry trends and advantages associated with n2 nitrogen generators.

The Versatility and Efficiency of N2 Nitrogen Generators

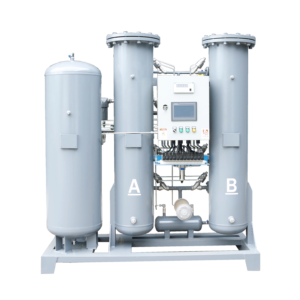

N2 nitrogen generators offer a wide range of applications across different industries. They are commonly used in food packaging, electronics manufacturing, pharmaceuticals, chemical processes, and many other sectors that require a reliable source of pure nitrogen gas. These generators utilize advanced membrane or pressure swing adsorption (PSA) technologies to efficiently extract nitrogen from compressed air.

One key advantage is their ability to provide on-site production of nitrogen gas at a lower cost compared to traditional methods such as liquid or cylinder supply. By eliminating the need for transportation and storage of bulky cylinders or cryogenic liquids, businesses can significantly reduce operational costs while ensuring a continuous supply of high-quality nitrogen gas.

Furthermore, N2 nitrogen generators offer enhanced control over purity levels. With adjustable settings, these systems can deliver varying degrees of purity tailored to specific industrial requirements. This flexibility allows manufacturers to optimize their processes without relying on external suppliers or compromising product quality.

Lingyu: A Leading Provider in N2 Nitrogen Generation Technology

When it comes to reliable and efficient N2 nitrogen generator solutions, Lingyu stands out as one of the leading providers in the industry. With years of experience and expertise in gas separation technology, Lingyu offers cutting-edge products that meet stringent quality standards.

Lingyu’s N2 nitrogen generators incorporate advanced PSA technology combined with intelligent control systems for optimal performance. Their systems ensure stable nitrogen production, high purity levels, and energy efficiency. Additionally, Lingyu provides comprehensive after-sales services including installation support, maintenance training, and technical assistance.

The Role of Compressed Air Dryer Manufacturers

Compressed air dryers play a crucial role in the overall performance of N2 nitrogen generators. These devices remove moisture from the compressed air before it enters the generator’s separation unit. By preventing water vapor from interfering with the gas separation process, compressed air dryers contribute to improved efficiency and reliability.

Leading compressed air dryer manufacturers understand this importance and offer specialized products designed specifically for use with N2 nitrogen generators. They provide advanced drying technologies such as refrigerated dryers or desiccant dryers that effectively eliminate moisture content from compressed air streams.

In conclusion, N2 nitrogen generators have become increasingly popular due to their versatility, cost-effectiveness, and ability to deliver high-purity nitrogen gas on-site. Companies like Lingyu have played a significant role in advancing this technology by providing reliable solutions tailored to specific industrial needs. Moreover, the collaboration between N2 nitrogen generator manufacturers and compressed air dryer manufacturers ensures optimal system performance for various applications across industries.