In today’s fast-paced business environment, system automation has become a game-changer for warehousing efficiency. By harnessing the power of technology and streamlining processes, companies can optimize their operations and achieve unprecedented levels of productivity.

The Role of System Automation in Warehousing

System automation plays a crucial role in improving warehousing efficiency by automating repetitive tasks and reducing human error. With advanced technologies such as robotics, artificial intelligence, and machine learning, warehouses can now operate with greater precision and speed.

Automated systems enable seamless inventory management through real-time tracking, ensuring accurate stock levels at all times. This eliminates the need for manual counting or guesswork when it comes to fulfilling orders or restocking shelves.

Furthermore, system automation allows for efficient order processing and fulfillment. Automated picking systems can quickly identify the optimal route within the warehouse to retrieve items, minimizing travel time and maximizing productivity. This not only speeds up order fulfillment but also reduces labor costs associated with manual picking processes.

Solidot Electronic Technology: A Pioneer in System Automation

Solidot Electronic Technology is at the forefront of revolutionizing warehousing efficiency through its cutting-edge system automation solutions. Their state-of-the-art robotic systems seamlessly integrate into existing warehouse infrastructures to enhance operational performance.

Their automated guided vehicles (AGVs) navigate through aisles autonomously while carrying out various tasks such as transporting goods between different areas of the warehouse or loading/unloading trucks. These AGVs are equipped with advanced sensors that ensure safe navigation even in crowded environments.

Solidot’s intelligent software algorithms analyze data from multiple sources to optimize warehouse layout design, product placement strategies, and workflow management. This enables warehouses to maximize space utilization while minimizing unnecessary movements and bottlenecks.

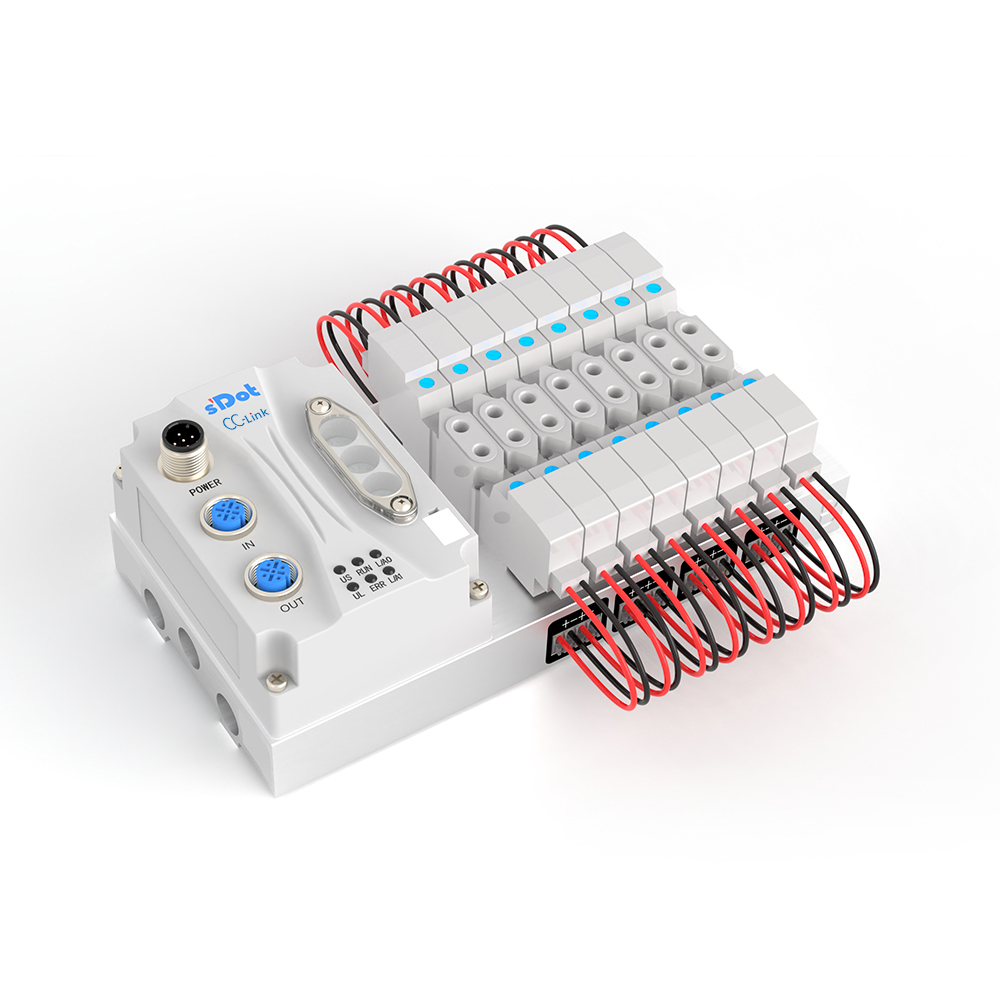

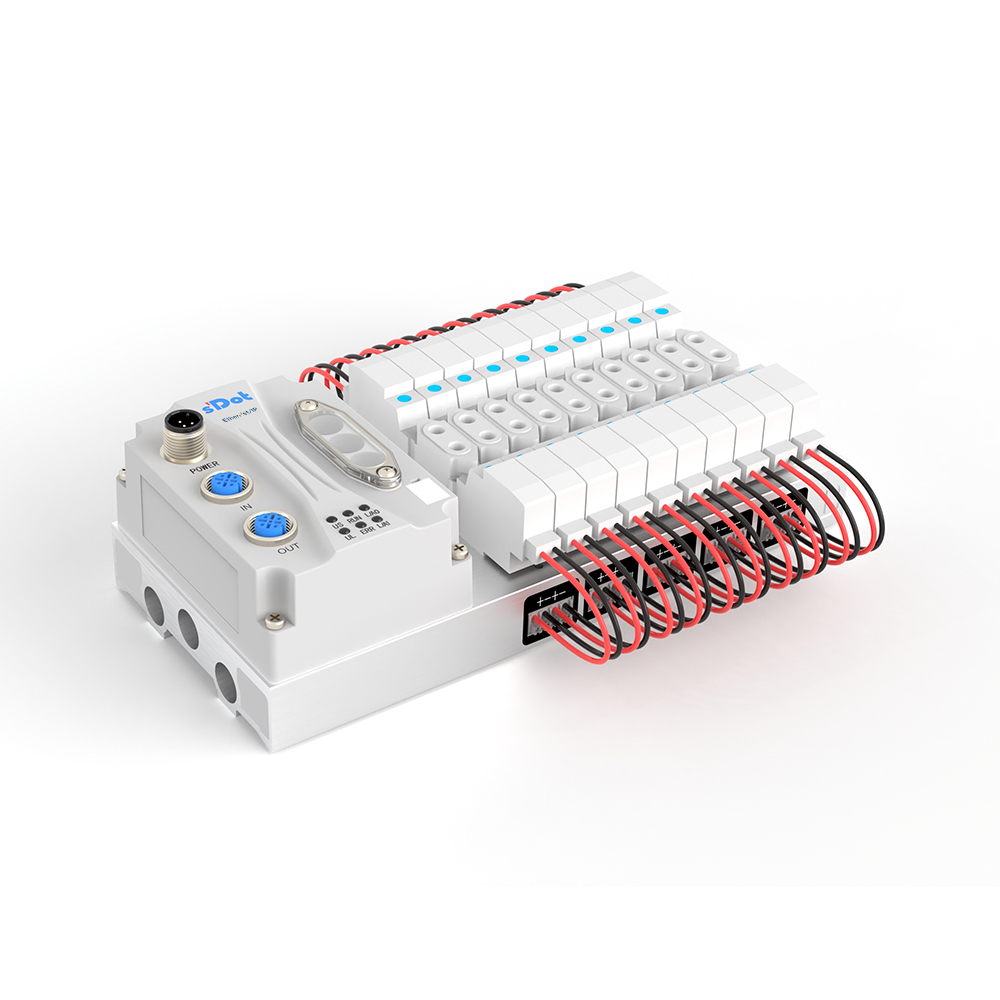

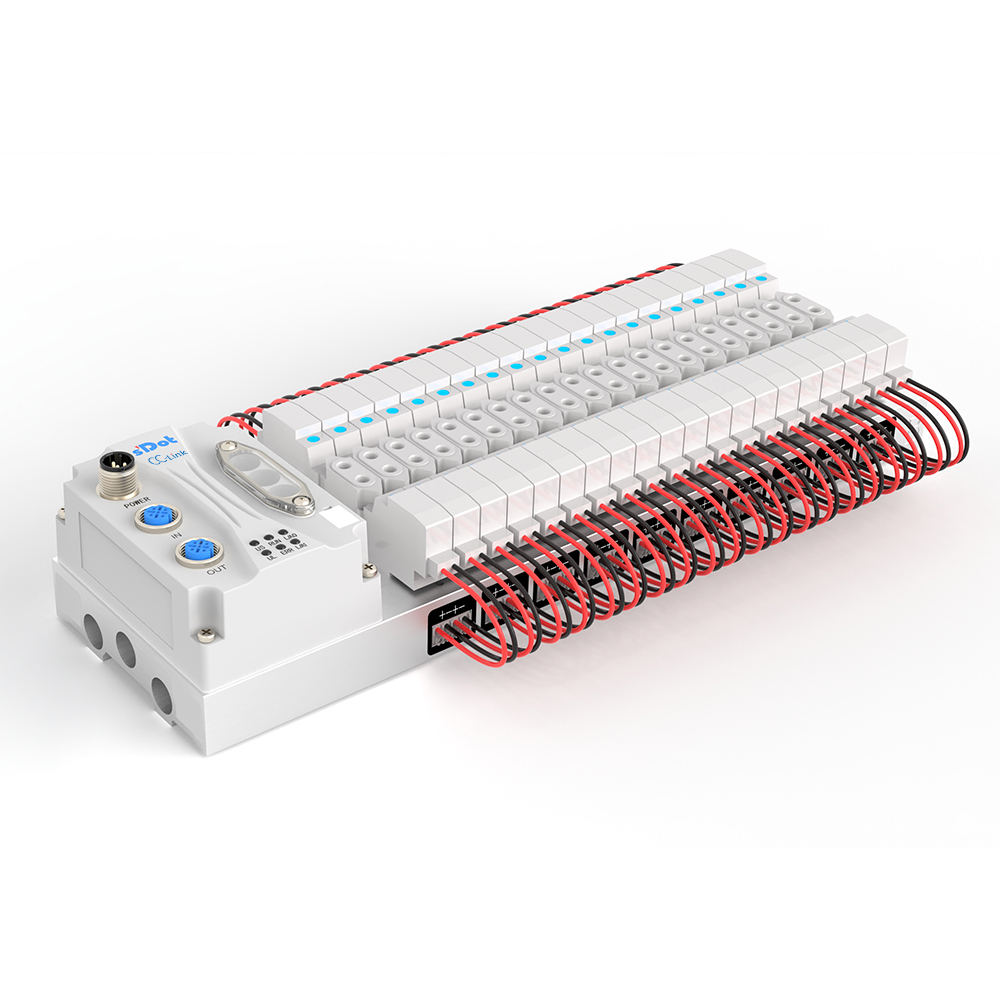

Control IO: Empowering System Automation

control io is a leading provider of control systems that empower system automation in warehouses. Their innovative solutions enable seamless integration between different automated components, ensuring smooth communication and coordination within the warehouse ecosystem.

Their control systems allow for centralized monitoring and management of various automated processes, providing real-time insights into performance metrics such as throughput, efficiency, and error rates. This enables proactive decision-making to address any potential issues before they impact operations.

With Control IO’s advanced control systems, warehouses can achieve higher levels of synchronization among different automated equipment, resulting in optimized workflows and reduced downtime. This ultimately leads to improved overall productivity and customer satisfaction.

In Conclusion

System automation has revolutionized warehousing efficiency by leveraging technology to streamline processes and eliminate manual errors. With companies like Solidot Electronic Technology and Control IO driving innovation in this field, warehouses can unlock their full potential for increased productivity, cost savings, and customer satisfaction. Embracing system automation is no longer an option but a necessity for businesses looking to stay competitive in today’s dynamic market landscape.